Enhancing Smart Manufacturing with Advanced Rotary Tables

In today's fast-paced manufacturing environment, Industry 4.0 stands at the forefront of technological innovation, transforming traditional manufacturing processes into smart, interconnected systems. Industry 4.0 leverages cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), and real-time data processing to create intelligent, efficient, and adaptive production systems. Within this transformative landscape, advanced rotary tables play a pivotal role, enhancing the capabilities of smart manufacturing setups.

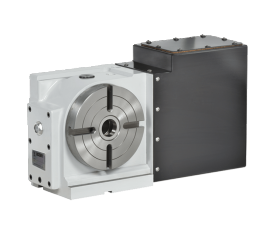

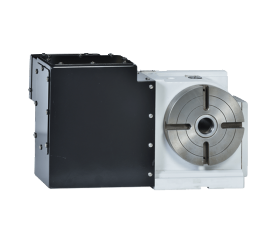

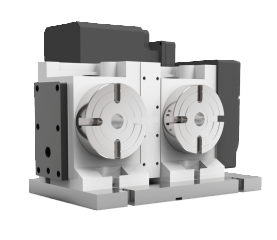

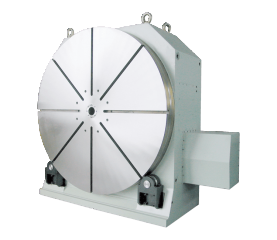

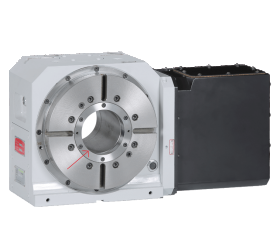

Advanced rotary tables, including hydraulic rotary tables, CNC index tables, rotary index tables, and indexing tables, are crucial components in modern manufacturing. These devices enable precise positioning and rotation of workpieces, facilitating complex machining tasks with high efficiency and accuracy. This article explores the benefits and applications of advanced rotary tables in smart manufacturing, emphasizing their integration with Industry 4.0 technologies.

The Role of Advanced Rotary Tables in Industry 4.0

Key Terms Defined

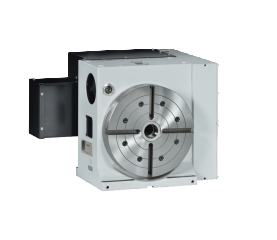

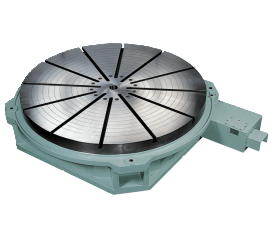

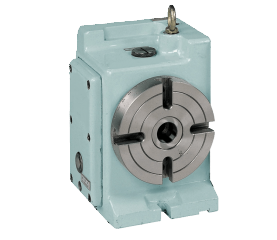

- Hydraulic Rotary Table:

A rotary table powered by hydraulic systems known for superior load handling and precision in heavy-duty machining tasks.

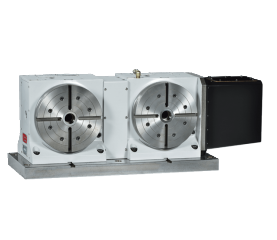

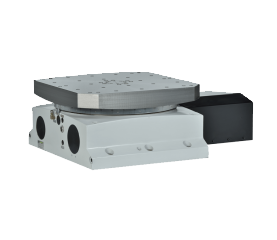

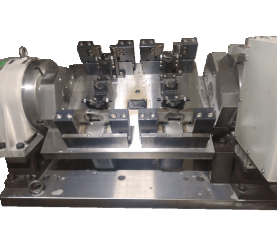

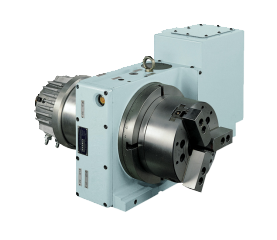

- CNC Index Table:

A computer-controlled indexing table allows automated and precise positioning of workpieces.

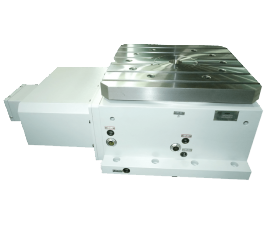

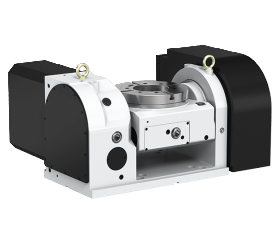

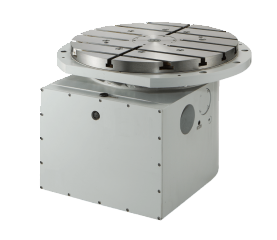

- Rotary Index Table:

A device that rotates a workpiece to various indexed positions, facilitating multi-axis machining operations.

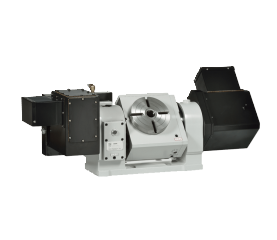

- Indexing Table:

A table that moves a workpiece to specific, pre-set positions, enabling consistent and accurate machining.

Integration with Industry 4.0 Technologies

Advanced rotary tables integrate seamlessly with Industry 4.0 technologies, enhancing manufacturing processes in several ways. IoT enables real-time monitoring and data collection from rotary tables, providing insights into machine performance and operational efficiency. AI algorithms analyze this data to predict maintenance needs and optimize machining parameters, reducing downtime and improving precision. Real-time data processing ensures immediate feedback and adjustments, maintaining optimal production conditions.

The practical implications of these integrations are significant. For instance, IoT sensors on rotary tables can monitor load conditions and predict potential failures, allowing for proactive maintenance. AI can optimize indexing by analyzing historical data and suggesting the most efficient machining paths. These advancements result in higher productivity, reduced maintenance costs, and improved product quality.

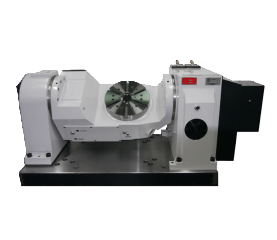

Hydraulic Rotary Tables: Power and Precision

Hydraulic Rotary Tables: Power and Precision

Hydraulic rotary tables are designed to handle heavy loads and perform precise machining operations. Their hydraulic systems provide powerful and smooth movement, essential for heavy-duty applications. These tables are particularly beneficial in industries such as automotive and aerospace, where machining large and heavy components is standard.

Specific Advantages

- Cost-Effective:

Hydraulic rotary tables are generally more budget-friendly than their electrical counterparts, making them a cost-effective choice for many manufacturers.

- Simple Structure:

The straightforward design of hydraulic rotary tables ensures ease of operation and maintenance, reducing downtime and operational costs.

- Pre-Regulated Indexing Positions:

These tables feature pre-set indexing positions, ensuring consistent and accurate angular increments, which is crucial for precision machining.

Hydraulic rotary tables are also known for their durability and reliability. Their robust construction can withstand harsh industrial environments, providing long-term performance and reducing the need for frequent replacements. This makes them an excellent investment for manufacturers looking to improve their machining capabilities while keeping costs in check.

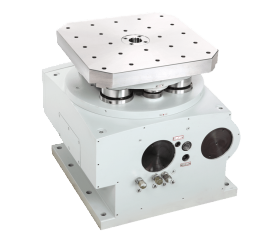

CNC Index Tables: Enhancing Automation and Accuracy

Functionalities and Benefits

CNC index tables are integral to automated manufacturing setups, enabling precise control over the positioning of workpieces. These tables enhance automation by allowing access to all sides of the workpiece with minimal manual intervention. This capability significantly reduces setup times and increases manufacturing throughput.

Specific Advantages

- Automation Enhancement:

CNC index tables facilitate complete machining process automation, minimizing setup time and enhancing efficiency.

- Single Machine Set-Up:

By enabling various machining tasks on a single machine, CNC index tables save time and cost, streamlining the production process.

- Accuracy Enhancement:

CNC index tables offer precise control, reducing tolerance errors, ensuring consistent part quality, and reducing waste.

CNC index tables are designed to integrate seamlessly with computer-aided manufacturing (CAM) software, allowing for easy programming and operation. This integration enables manufacturers to quickly adapt to changing production requirements and produce complex parts with high precision. Additionally, CNC index tables can be equipped with advanced features such as automatic tool changers and probing systems, further enhancing their versatility and efficiency.

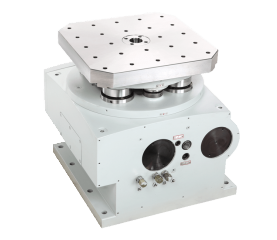

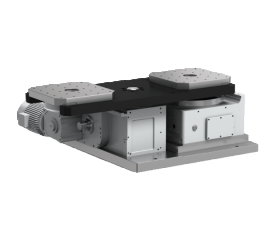

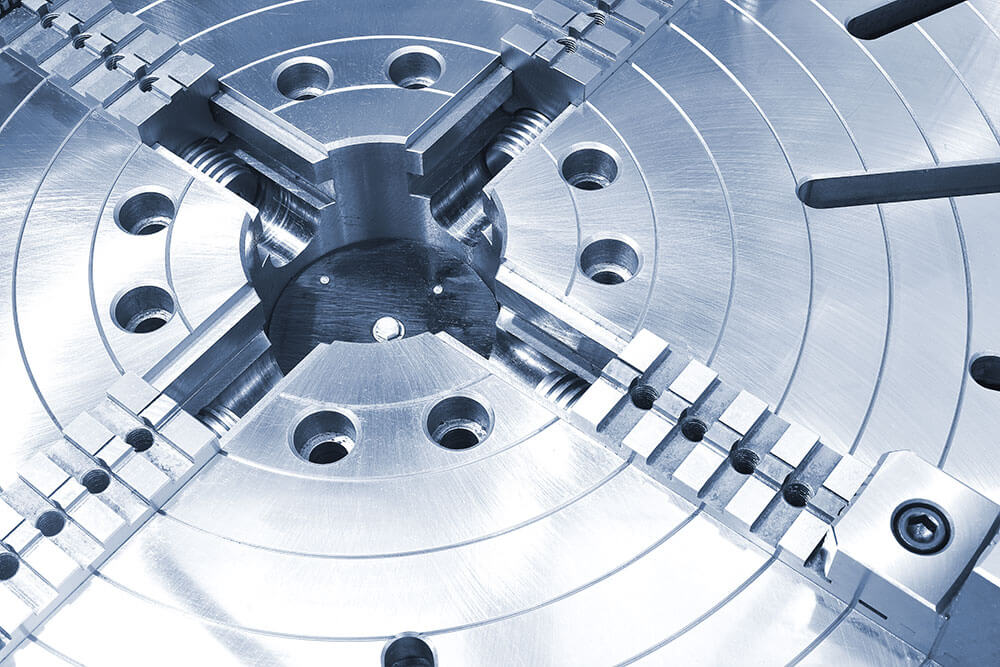

Rotary and Indexing Tables: Maximizing Productivity

Differences and Applications

While both rotary index tables and indexing tables are used to position workpieces, their applications can vary. Rotary index tables are ideal for continuous machining operations, allowing for multi-axis machining and reducing the need for multiple setups. On the other hand, indexing tables are used to move workpieces to specific, predetermined positions, ensuring accuracy and consistency in high-speed manufacturing environments.

Specific Advantages

- Multi-Axis Machining:

Rotary index tables enable complex part geometries by allowing multi-axis machining, which reduces the need for multiple setups and improves efficiency.

- Continuous Machining:

These tables eliminate downtime between operations, boosting productivity by allowing continuous machining processes.

- Batch Processing:

Indexing tables streamline the production of identical parts, maximizing output and ensuring uniformity across batches.

- Reduced Manual Intervention:

Automated indexing and positioning minimize human error, improving overall production quality and consistency.

Rotary and indexing tables are also known for their flexibility and adaptability. They can be configured to handle a wide range of workpiece sizes and shapes, making them suitable for various industries, from electronics to heavy machinery. By enabling quick and precise repositioning of workpieces, these tables help manufacturers meet tight production deadlines and maintain high productivity levels.

Conclusion

Advanced rotary tables, including hydraulic rotary tables, CNC index tables, rotary index tables, and indexing tables, are essential components in the intelligent manufacturing landscape shaped by Industry 4.0. Their integration with IoT, AI, and real-time data processing technologies enhances precision, efficiency, and productivity in modern manufacturing processes.

Hydraulic rotary tables offer robust and cost-effective solutions for heavy-duty applications, while CNC index tables provide automation and accuracy benefits essential for high-precision manufacturing. Rotary and indexing tables further maximize productivity by enabling multi-axis machining, continuous operation, and efficient batch processing. These advanced rotary tables empower manufacturers to achieve greater efficiency, reduce operational costs, and maintain competitive advantage in an increasingly digital and interconnected world.

Manufacturers looking to stay competitive and elevate their production capabilities should consider incorporating these advanced rotary tables into their operations. HOSEA offers a range of state-of-the-art rotary tables that integrate seamlessly with Industry 4.0 technologies, ensuring optimal performance and efficiency.

To learn more about how HOSEA's advanced rotary tables can enhance your manufacturing processes, contact us today. Reach out today and discover innovative solutions that will transform your production facilities and keep you ahead in the rapidly evolving manufacturing industry.

By embracing the power of advanced rotary tables, manufacturers can unlock new levels of productivity, precision, and efficiency, setting the stage for a smarter, more connected future in manufacturing.